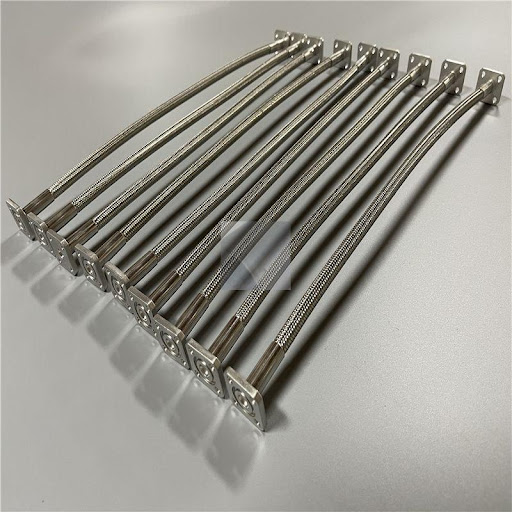

Tubing is one of the most important and essential components of a piping system. When it comes to replacing tubing, it’s important to make the process as efficient and easy as possible. In this article, we’ll take a look at some of the ways that PTFE tubing manufacturers are making the process of replacing tubing faster and easier.

What is PTFE Tubing and Why Is It So Popular?

PTFE tubing is a type of tubing made from a polymer that is very thin and has a high melting point. This makes it a great material for use in many applications where heat and pressure are involved, such as in the medical industry and oil and gas production. PTFE tubing is also popular for its durability and resistance to corrosion.

How PTFE Tubing is Made

The process of replacing tubing is a time-consuming and costly task, but tubing manufacturers are making the process of replacing your tubing faster than ever before. PTFE tubing is a popular choice for many applications due to its light weight and resistance to chemical corrosion. Here are three ways that flexible PTFE tubing manufacturers are making the process of replacing your tubing faster:

1. Automation: Many companies are using automation technology to speed up the process of manufacturing new or replacement tubing. This technology allows for faster production lines and increased accuracy. By automating the process, manufacturers can ensure that each tube is produced to specifications and meets customer needs.

2. Custom Manufacturing: Some manufacturers are using custom manufacturing technology to create unique designs for their products. This allows them to create products that are not typically available on the market. By creating unique products, manufacturers can reach a wider audience and increase sales overall.

3. Rapid Prototyping: Another way that manufacturers are making the process of replacing tubing faster is by using rapid prototyping technology. This technology allows for quick testing of concepts before they are developed into full-blown products. By quickly testing

The Different Types of PTFE Tubing

There are a variety of types of PTFE tubing, each with its own advantages and disadvantages. Here’s a look at the most common types:

-Teflon®: Teflon® is the most popular type of PTFE tubing, and it has many advantages. It’s resistant to chemicals, heat, and oil, which makes it perfect for use in high-pressure applications. Plus, it has a low coefficient of friction, which means it slides easily along surfaces.

-PTFE Copolymer Tubing: PTFE Copolymer Tubing is a blend of two types of PTFE, making it stronger and more resistant to chemicals than pure Teflon® tubing. It also has a lower coefficient of friction than Teflon®, so it’s less likely to stick during installation.

-PTFE Rigid Tubing: PTFE Rigid Tubing is made from 100% pure PTFE and is the strongest type of tubing available. It’s also the most expensive and difficult to work with, due to its stiffer texture and resistance to wear.

The Advantages of PTFE Tubing

PTFE tubing is a great material to use in many applications, as it offers many advantages over other materials. Here are some of the reasons why PTFE tubing is a popular choice among manufacturers:

-PTFE tubing is durable and resistant to chemicals and oil.

-PTFE tubing is lightweight, making it easy to handle and transport.

-PTFE tubing has a low thermal conductivity, meaning it doesn’t lose heat quickly.

-PTFE tubing is non-toxic and can be safely used in many applications.

The Disadvantages of PTFE Tubing

When it comes to choosing the right tubing for your needs, there are a few things you need to consider. For one, PTFE is a great material for many applications because of its low friction and heat resistant qualities. However, this material also has some disadvantages that you should be aware of when choosing it for your plumbing needs.

The first disadvantage is that PTFE tubing may not be as durable as other types of tubing. This is because PTFE is less resistant to chemicals and liquids than other materials, which can lead to damage over time. Additionally, PTFE tubing may also become brittle over time, which can make it difficult to repair or replace.

The second disadvantage of PTFE tubing is that it conducts heat poorly. This means that PTFE will not transfer heat as well as other materials when used in hot environments, such as in a plumbing system. This could lead to problems such as overheating and possible Fires. Additionally, PTFE tubing may also become brittle under high temperatures, which can lead to leaks and further damage.

How to Replace Your PTFE Tubing

PTFE tubing is a type of plastic tubing that can be used to transfer fluids and gases. Tubing made with PTFE is often used in industrial and scientific applications because it is resistant to chemicals, heat, and corrosion.

When your PTFE tubing needs to be replaced, there are several steps you can take to make the process easier. Here are four tips from some of the biggest PTFE tubing manufacturers on how to replace your tubing quickly and efficiently:

1. Get a replacement kit. Many manufacturers now offer replacement kits that include all the necessary parts for replacing your tubing. This makes the process easier since you don’t have to search for individual components.

2. Preferably use certified materials. When replacing your tubing, make sure to use certified materials that are free from harmful chemicals and toxins. These materials will provide longer life and higher performance for your equipment.

3. Follow the manufacturer’s instructions closely. Always follow the manufacturer’s instructions when replacing your tubing, even if you think you know how to do it correctly. Incorrectly replacing your

Conclusion

Thank you for reading this article on how flexible PTFE tubing manufacturers are making the process of replacing your tubing faster. By using PTFE tubing, you’re ensuring that your plumbing system will last longer and remain in good condition. Not to mention, it’s also much easier to replace your tubing than other types of plumbing systems. If you’re having any trouble with your plumbing system, don’t hesitate to give one of these manufacturers a call!