The 3D printer has been there since the 1980s. Charles W. Hull was the first person to invent and create the first ever 3d printing part. This type of manufacturing is also called addictive. 3d printing is simply a process where you create a three-dimensional solid object from a computer design. You get to make this dimensional object layer by layer from a digital file. If you compare 3D printers to other technologies, they are more advantageous.

Materials to Use in 3D Printing

In the beginning, plastic was the only material used, but there have been some changes due to technology. There is a wide range of 3D materials, such as thermoplastics, resins, metals, gold, and ceramics—the list of what materials to use keeps growing daily.

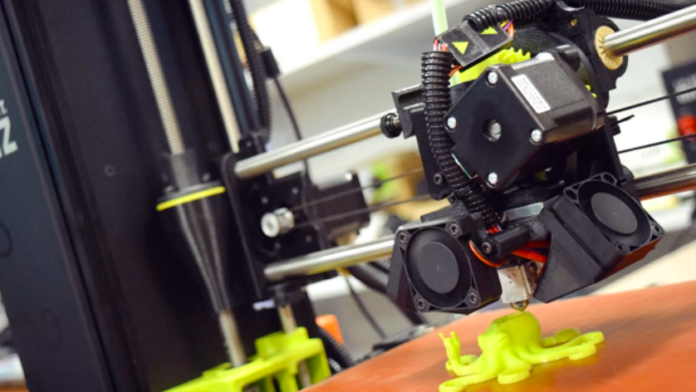

How Does A 3D Printer Work?

3D printing objects have gone through some addictive processes. During this printing process, you stack layers of materials on top of each other through a nozzle. The nozzle rotates under the control of the computer. Before adding another layer, you have to allow the first layer to dry. You repeat the whole process until you get the required size.

What Are The Pros Of Using A 3D Printer?

If you make a 3d printer comparison with traditional manufacturing methods, you get to know the range of benefits 3d printing offers, especially during the production process. Below are some advantages of using 3D printing.

- They Are Speedy

It is one of the advantages of using a 3d printer. They can design, manufacture and customize parts within a short period. If you want to modify your design, you can do so without affecting the manufacturing speed. They are cheap and quicker if you compare them to machining prototypes.

- Workable Design

Traditional manufacturing limits the number of designs to use, but with 3d, it is different. Restrictions do not apply to 3d because you can customize any format you need since the computer aids it. It can create anything as long as its fits within its build volume. It is not the case with traditional manufacturing because any slight change in the design will change many things like the die, mold, and tool.

- Relatively Affordable

The cost of production in 3d printers is affordable. For the price to be low, you must consider several factors like time and materials. A closer look at 3d printer comparison with some traditional prototyping like injection molding, then you sees it’s cheaper. Injection molding and CNC machining require expensive machines and qualified personnel to operate the machines. The case is different with 3d printing since it only requires one or two devices and fewer people to work.

- Does Not Pollute The Environment

3d printing technology is environment friendly since it recycles plastics, mine, and cement in their production. It does not necessarily require brand-new materials to come up with something unique. If you need fast and high-quality products, 3D printing manufacturing technology is the choice. You get a product that pleases you. You will save your time and money.