Nearly 5.4 million hybrid and millions of plug-in electric vehicles have been sold, and all will need to be repaired or replaced at some point.

A motor doesn’t need to die to need fixing – it may have just burnt out because of wear and tear. If a motor has been damaged through misuse, you must take action to ensure that it functions safely.

One common way to restore and repair a motor is to wind or rewind it. But what exactly is motor rewinding?

Keep reading to learn all about rewinding and what it is for.

The Principles of Motor Rewinding

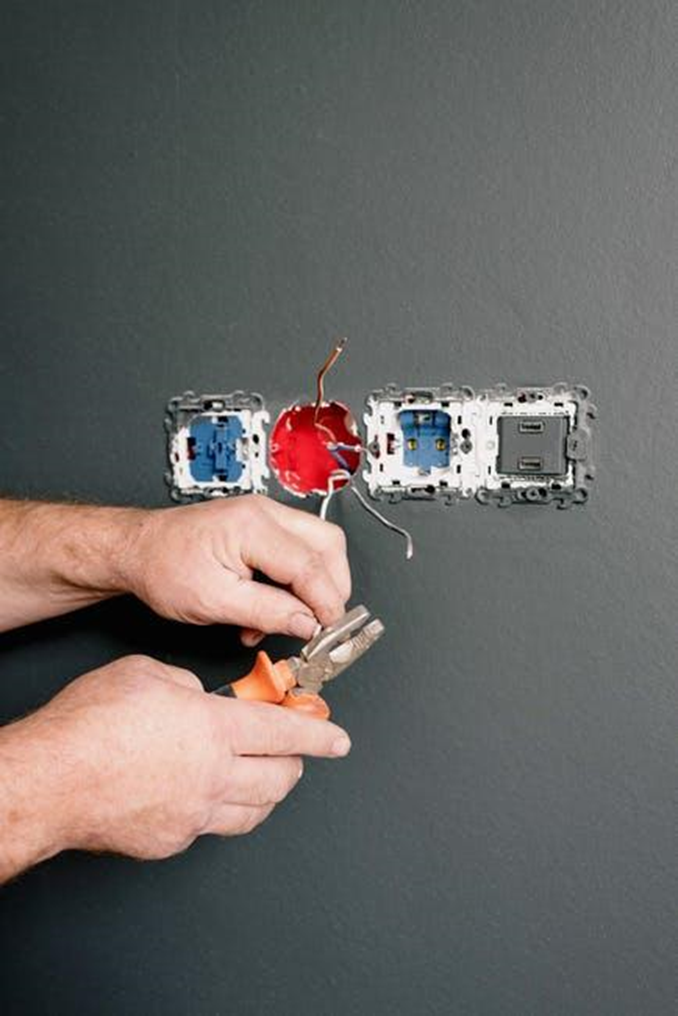

Motor Rewinding is removing, inspecting, and replacing the winding of an electric motor with a new one. This ensures efficient operation, improved performance, and longer motor life.

The Principles of Motor Rewinding involve removing the existing motor winding and cleaning the lamination and frame. It also includes inspecting the motor for any damage or existing defects.

If defects are found, the defective parts can be repaired or replaced following the motor manufacturer’s instructions. Houghton International helps to restore a motor while preserving its service life.

Types of Motor Rewinding

There are two types of motor rewinding: field or armature winding. Field winding is the process of rebuilding or replacing the field coil of the motor.

Armature winding is the rebuilding or replacing of the amateur windings of the motor. Both must guarantee the motor’s best performance, reliability, and efficiency.

Each type of rewinding has particular specifications. This must be met for the motor to be repaired appropriately.

Factors that Affect Motor Rewinding

Factors that affect motor rewinding include the type and size of the motor and the environment of the motor. It also provides for the kind of insulation used and the number of windings that need to be replaced.

The motor’s operating temperature, the type of load, the winding materials, and the condition of the motor are all critical considerations when assessing whether a motor needs rewinding. When rewinding, it is always best to consult with a skilled electric motor company.

Advantages of Motor Rewinding

Motor rewinding offers numerous advantages when it comes to cost-effectiveness and energy efficiency. Not only are energy costs reduced, but motor components also last longer.

This is due to the increased efficiency of motor rewinding, reducing the need for frequent repairs and replacements. Furthermore, you can complete repairs and replacements quicker than traditional motor replacements.

It allows for increased production time and schedule adherence. Motor rewinding also helps to reduce the amount of waste and pollution caused by discarded motors and their components.

Making it a greener and more cost-effective option for many businesses. Rewinding can also prevent breakdowns, save energy and help to make the motor more reliable.

Doing a Motor Rewinding

Motor rewinding is a cost-effective solution for repairing aging or damaged motors. With fast turnaround and a commitment to maintaining quality standards, electric motor rewinding is an excellent option for those needing efficient repair.

Learn more about motor rewinding and how it can help extend the life of motors for increased efficiency. Contact a qualified motor rewinding professional today to find out more.

For more advice, visit the topics tab on this page.