Well, that’s what I reflect on consideration on brakes. If you’ve got a vehicle with an effective engine that can run rapidly as a cheetah however doesn’t have sufficient effective brakes to prevent it OR manage it, you higher promote it ASAP.

So, these days in here, we’ll see what are brakes & the styles of brakes!

What are Brakes?

Brakes are mechanical gadgets that take in the kinetic power of the gadget & convert it into another shape of power (commonly heat) as a way to prevent a shifting gadget.

They aren’t most effectively used to prevent a shifting gadget however additionally to save you a movement of any a part of a specific gadget.

We commonly see them established at the top of the shafts & axles of vehicles.

Types of Brakes: –

1. Pivoted kind Shoe brake: –

In this kind, a block OR a shoe is connected to a lever & is pressed in opposition to a rotating drum(wheel). One-stop of the lever is pivoted at a factor (at the chassis somewhere) & pressure(P) is implemented on the opposite stop. Human applies pressure(F) through pedals however isn’t always sufficient to provide the braking torque. Here comes the lever; the lever multiplies the pressure(F) via way of means of a few regular(C) to provide more pressure(P) to generate sufficient stress among drum & shoe!

More the lever distance, much less the human effort! This is vital at the same time as designing the ergonomics of the car!

The regular C relies upon the duration of the lever, the distance among touch factor of the shoe, and the drum & pivot factor. In the animation, my hand applies pressure(F) & the pressure which gets applied to the drum is an awful lot more pressure(P)!

Another model of those brakes incorporates 2 footwear on the other aspect to grow the braking torque. Such kinds are referred to as Pivoted kind double shoe brake. They are extensively utilized in trains even now. Look across the wheels subsequent time at the same time as you travel; they’re pretty clean to notice!

2. Band brake

A band brake, as visible in our animation essentially includes a lever & a band which receives rubbed in opposition to the drum(wheel). One-stop of the lever is connected to a repair factor additionally referred to as a pivot factor & pressure is implemented to the opposite stop. The band includes a bendy leather-based belt OR metal coated with friction material. The band surrounds the drum with a few clearances.

As quickly because the pedal is pressed, the band receives rubbed in opposition to the drum which ultimately involves rest.

3. Disc brakes

Disc brakes are the maximum extensively used brakes & may be visible in nearly every software consisting of bicycles, bikes, motors, etc.

Here in disc brakes, 2 pads owning excessive friction are used rather than footwear. These pads are organized such that the disc is precisely established among the 2 brake pads. The brake pads are connected & operated with the assist of a couple of levers, jaws & springs.

We should see withinside the animation that after we press the brake pedal, the movement is transmitted through levers & the brake pads practice stress at the disc from each side. The braking pressure then attempts to retard the movement of the disc thereby bringing the car to a halt.

In motors, the brake pads are normally established withinside the calipers in which they’re driven with the assist of hydraulics. Brake fluids are used to push the pads in the direction of the disc.

An animation of the identical is blanketed beneath in hydraulic braking.

4. Band & block brake

The running of band & block brake is quite an awful lot much like band brakes besides that they incorporate blocks among the band & drum. The blocks perhaps timber or another friction-coated material.

More the variety of blocks extra is the braking pressure & accordingly better retardation. These styles of brakes have been extensively utilized in trains.

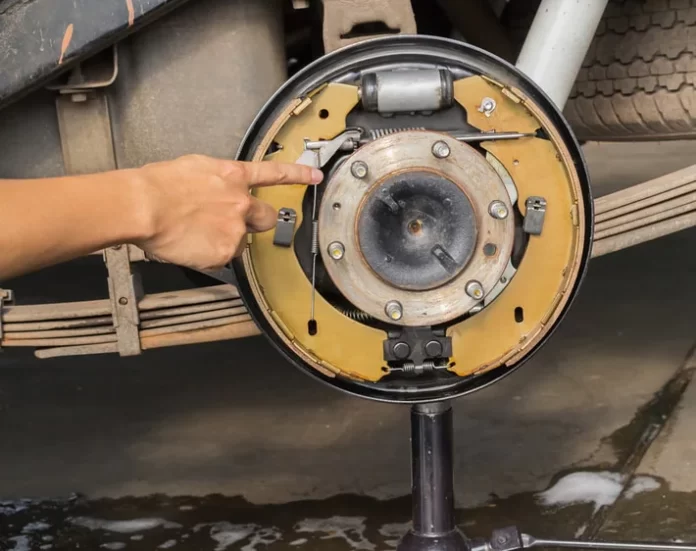

5. Internally increasing brakes

Here, the friction-coated footwear is positioned in the rotating drum. Both diametrically contrary footwear is C-shaped.

One-stop of each footwear are constant on a factor i.e., their fulcrum (decrease aspect in our animation).

While the opposite stop is attached to cam operated lever & a retractable spring (a top aspect of the drum in animation). Click here

In our animation, while we rotate the cam the brake footwear gets extended in a radially outward route accordingly making use of stress at the internal floor of the drum. A pressure referred to as braking pressure receives implemented because of this implemented stress & the drum’s movement is added to rest. When we launch the cam, the spring tending to contract, pulls the footwear in the direction of itself permitting the drum to rotate again.