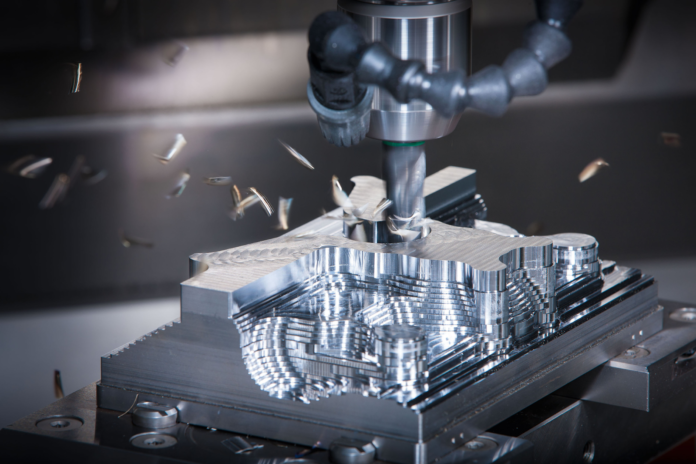

Here are some of the benefits of using CNC metal laser cutters in the manufacturing industry, including lower costs and less labor required. For example, it takes less time to produce moldings without having to manually use a jig and various other tools.

What are the advantages and benefits of CNC for manufacturing?

Manufacturing maquettes, prototypes and custom work all run way smoother, better and faster with CNC machines. When more accurate tolerances are needed in comparison to conventional methods, then CNC machines sure are the right option. Increased levels of precision are also achievable with CNC machining.

CNC machining is faster and more accurate than traditional manufacturing processes. It can quickly reduce time, labor, and material costs without sacrificing quality because of the precision with which it can make any ideal cuts needed. CNC allows you to make custom orders on an individual basis as opposed to using a mass produced mold.

Using CNC in manufacturing

Continuously operated numerically controlled machining centers, or CNC mills, are used across many fields and for a variety of objectives. One of these fields is wood working. Using CNC to make lumber from different types of wood sources allows the manufacturers to control how their product looks, changes its shape, and imparts its own unique texture. CNC (Computer Numerical Control) machines are used to create many industrial strength components.

These machines allow a user to quickly design and produce parts, like molds, support structures, and other tools needed for production. This can help reduce the need for material stock that increases manufacturing costs. Additionally, CNC machines can use the same high-strength steel that is normally used in manufactured products. Not only has this changed the way production happens, but it has also reduced cost by eliminating waste in component materials (like aluminum)

Different types of CNC machines

There are really many different types of CNC machines out there. There are also different software packages and methodologies that use the specific machine to get a particular manufacturing process done. These automated processes can help reduce errors, while lowering costs too! Replacing traditional wood forming methods with CNC machining technologies has helped to cut the cost of production, speed up production times, reduce waste, and produce tighter tolerances.

Conclusion

The great thing about CNC-Machined Wood is that it doesn’t wear out. Cutting expenses and space wasted is only just the tip of the iceberg with this product. It replaces materials in production from metal to plastic, saving money hand over fist One way to cut costs for woodworking projects is through CNC-machined wood. This technology can produce a massive range of shapes, sizes, and design options from a single block of material today, unlike the handbook and chiseling process that can take weeks or even years to create complicated designs manually.